Installation Qualification Template

Installation qualification template - Performance qualification is a part of equipment validation process and there are a number of reasons why pharmaceutical plants should perform it. Get pro membership for only $9.99. The operational qualification protocol is a collection of test cases used to verify the proper functioning of a system. Solid waste storage and disposal; Overview of the c&g 2357 nvq level 3 electrical installation testing structure. A specific process will consistently produce a product meeting its predetermined specifications and Concrete, paint, and stucco washout and waste disposal; Service life cycle management is a critical element when purchasing your equipment. Operational qualification is usually performed before the system is released for use. And dewatering operations) and indicate for each activity the associated pollutants or pollutant constituents (e.g., sediment, fertilizers, pesticides, paints, caulks, sealants, fluorescent light.

3.4 the portfolio.3.4.1 guidance on collation; An installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as specified, and integrated in the manufacturing facility calibration and maintenance systems. First of all, at the end of the day, if the companies intend to deliver quality products, then it becomes an ethical obligation for them to put their equipment through the performance qualification. Proper life cycle management starts with the proper installation of the equipment and basic user training, which is followed by routine preventative maintenance visits. Built and installed in compliance with their design specifications (this constitutes installation qualification or ‘iq’) and that they operate in accordance with their design specifications (this constitutes operational qualification or oq).

Creation of Installation Qualification Protocols

Performance qualification is a part of equipment validation process and there are a number of reasons why pharmaceutical plants should perform it. Operational qualification is usually performed before the system is released for use. Get pro membership for only $9.99.

Senior Estimator Resume Samples QwikResume

The operational qualification protocol is a collection of test cases used to verify the proper functioning of a system. The operational qualification test requirements are defined in the functional requirements specification. A specific process will consistently produce a product meeting its predetermined specifications and

Writing Compliant IQ/OQ/PQ Protocols M A N O X B L O G

Overview of the c&g 2357 nvq level 3 electrical installation testing structure. Proper life cycle management starts with the proper installation of the equipment and basic user training, which is followed by routine preventative maintenance visits. It does not matter what industry you are in, pharma, biopharma, university, or food & beverage;

ISO 13485 Document Control Procedure Bundle

Solid waste storage and disposal; Concrete, paint, and stucco washout and waste disposal; Get pro membership for only $9.99.

Nvq Level 3 Certificate certificates templates free

And dewatering operations) and indicate for each activity the associated pollutants or pollutant constituents (e.g., sediment, fertilizers, pesticides, paints, caulks, sealants, fluorescent light. Concrete, paint, and stucco washout and waste disposal; First of all, at the end of the day, if the companies intend to deliver quality products, then it becomes an ethical obligation for them to put their equipment through the performance qualification.

IOPQ Laminar Air Flow Validation Template Sample by Pharmi Med Ltd

The operational qualification protocol is a collection of test cases used to verify the proper functioning of a system. Transcelerate is excited to announce our 2021 release! $19.99 resume coach review credit.

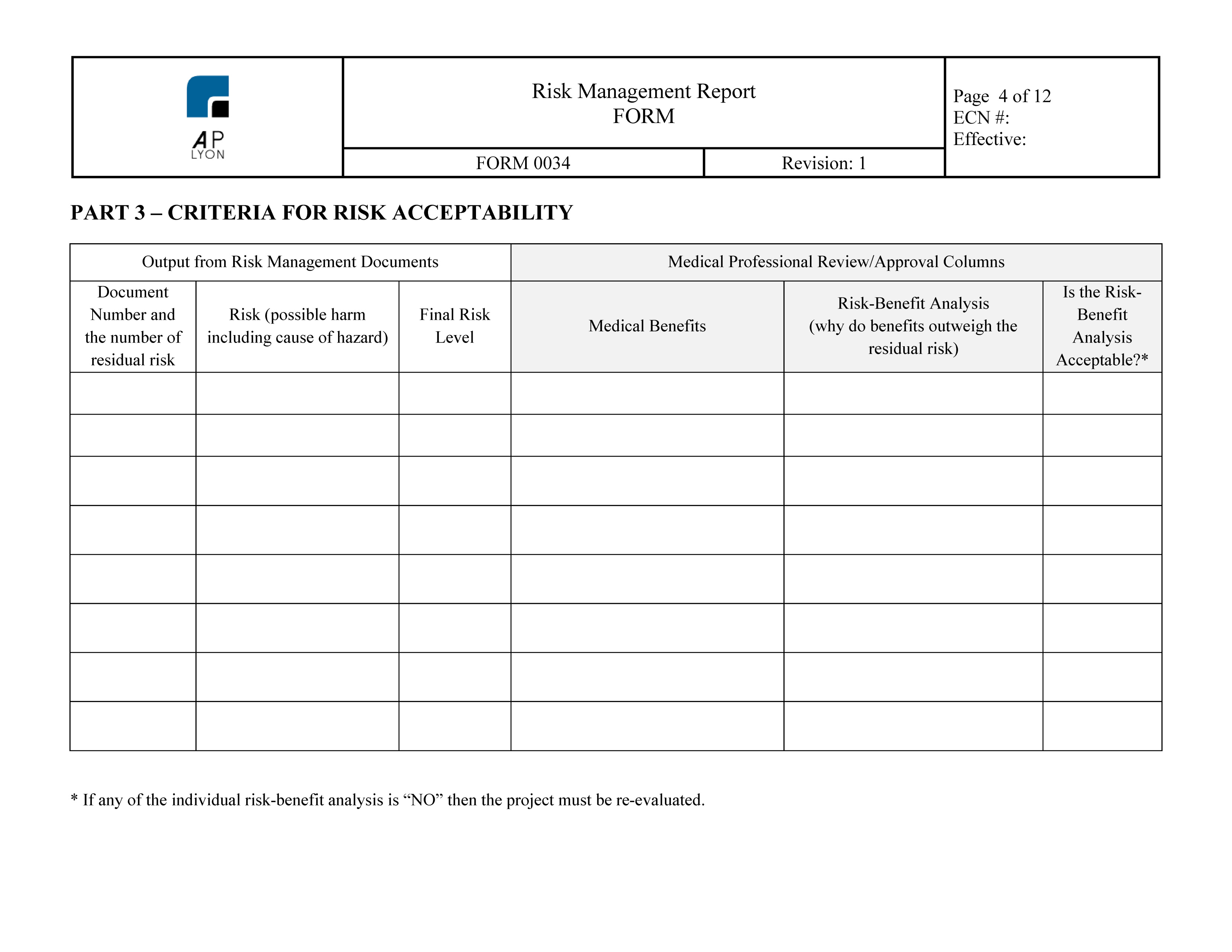

ISO 14971 Risk Management Forms

Also includes reference to the final am2 assessment. Overview of the c&g 2357 nvq level 3 electrical installation testing structure. Built and installed in compliance with their design specifications (this constitutes installation qualification or ‘iq’) and that they operate in accordance with their design specifications (this constitutes operational qualification or oq).

ISO 13485 Document Control Procedure Bundle

Operational qualification is usually performed before the system is released for use. $19.99 resume coach review credit. And dewatering operations) and indicate for each activity the associated pollutants or pollutant constituents (e.g., sediment, fertilizers, pesticides, paints, caulks, sealants, fluorescent light.

$19.99 resume coach review credit. The operational qualification protocol is a collection of test cases used to verify the proper functioning of a system. Service life cycle management is a critical element when purchasing your equipment. Get pro membership for only $9.99. Operational qualification is usually performed before the system is released for use. First of all, at the end of the day, if the companies intend to deliver quality products, then it becomes an ethical obligation for them to put their equipment through the performance qualification. Performance qualification is a part of equipment validation process and there are a number of reasons why pharmaceutical plants should perform it. Transcelerate is excited to announce our 2021 release! Solid waste storage and disposal; Concrete, paint, and stucco washout and waste disposal;

The operational qualification test requirements are defined in the functional requirements specification. Overview of the c&g 2357 nvq level 3 electrical installation testing structure. A specific process will consistently produce a product meeting its predetermined specifications and 3.4 the portfolio.3.4.1 guidance on collation; Also includes reference to the final am2 assessment. An installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as specified, and integrated in the manufacturing facility calibration and maintenance systems. Built and installed in compliance with their design specifications (this constitutes installation qualification or ‘iq’) and that they operate in accordance with their design specifications (this constitutes operational qualification or oq). And dewatering operations) and indicate for each activity the associated pollutants or pollutant constituents (e.g., sediment, fertilizers, pesticides, paints, caulks, sealants, fluorescent light. It does not matter what industry you are in, pharma, biopharma, university, or food & beverage; Proper life cycle management starts with the proper installation of the equipment and basic user training, which is followed by routine preventative maintenance visits.