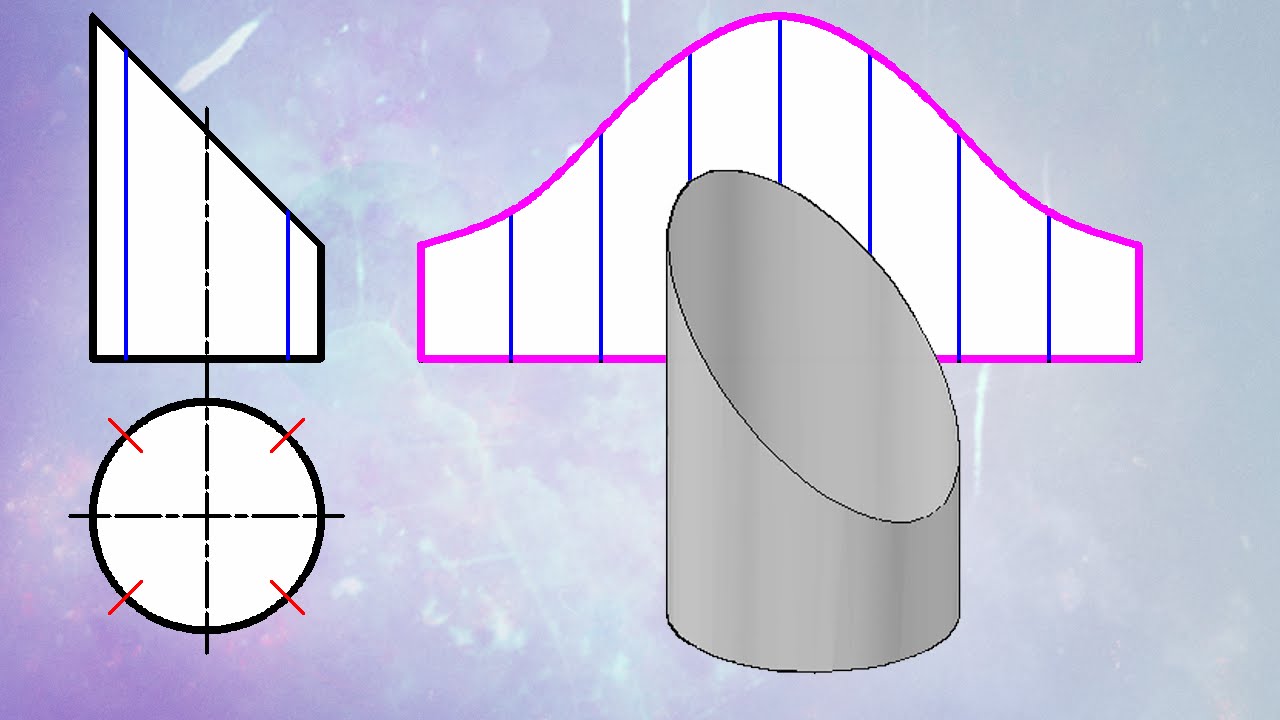

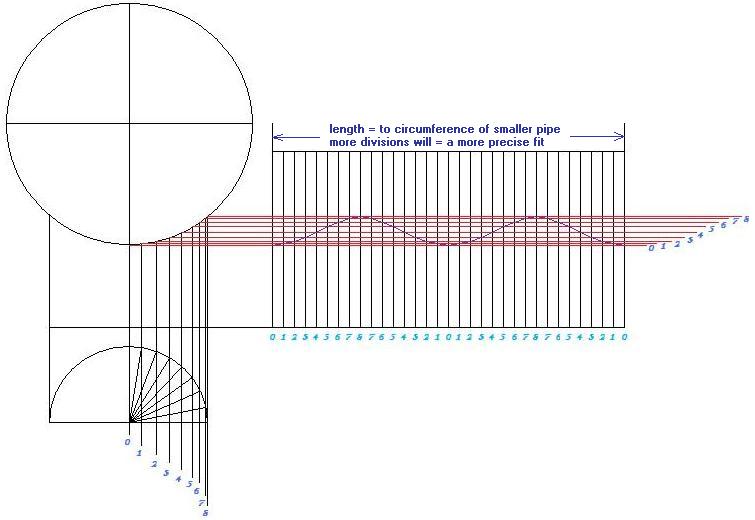

Pipe Coping Template

Pipe coping template - A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. This allows the workpiece to be transferred between machining (or. Also, a metal frame finished in wood or metal is sometimes used. [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of. The primary use of a center is to ensure concentric work is produced;

Template To Miter Pipe Pipe Template Layout Youtube

The primary use of a center is to ensure concentric work is produced; [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of. This allows the workpiece to be transferred between machining (or.

Tube Coping Calculator Some Tips For Notching Tube Accurately Page 2

[citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of. This allows the workpiece to be transferred between machining (or. A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.

Coping notch diagram Mini ramp, Skate ramp, Skateboard ramps

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of. This allows the workpiece to be transferred between machining (or.

Saddle Pipe

The primary use of a center is to ensure concentric work is produced; This allows the workpiece to be transferred between machining (or. [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of.

Tube Coping Calculator / Tube Notching Best Tools Tips And Tricks Tube

Also, a metal frame finished in wood or metal is sometimes used. A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of.

Pin on Skateboards

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of. This allows the workpiece to be transferred between machining (or.

How to Build a DIY Micro Quarter Pipe (With Ramp Plan) HowTheyPlay

The primary use of a center is to ensure concentric work is produced; Also, a metal frame finished in wood or metal is sometimes used. A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.

Cardboard Quarter Pipe 7 Steps Instructables

Also, a metal frame finished in wood or metal is sometimes used. The primary use of a center is to ensure concentric work is produced; [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of.

Also, a metal frame finished in wood or metal is sometimes used. The primary use of a center is to ensure concentric work is produced; [citation needed]most commercial and contest ramps are surfaced by attaching sheets of some form of. This allows the workpiece to be transferred between machining (or. A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis.they usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.